Jiangsu Sea Lion Machinery Co., Ltd. specializes in industrial washing equipment

Provide Customers with Efficient, Energy-Saving and Intelligent Washing Solutions

Categories

-

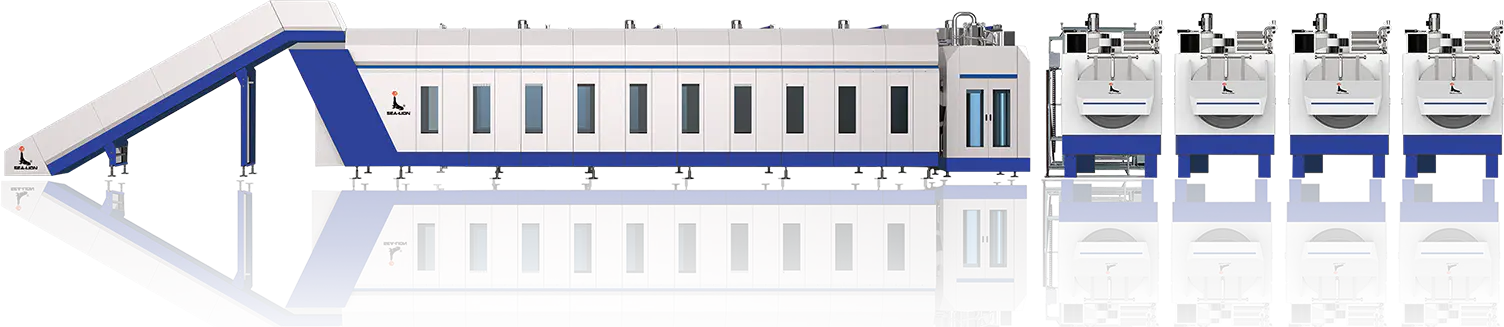

Main TunnelSuitable for high-quality washing of all kinds of textiles. Linen transference is done from the bottom without blockage inside the system. The washing quality has improved greatly thanks to the perfect combination of the downstream and upstream.Because of the application of water cycle technology, water consumption and steam consumption have been greatly reduced.100 processing programs have been built in the controller, making control of the whole procedure simpler and more intelligent. And programming can be done freely as desired. 1200-1800kg of linen can be processed per hour.

-

Automatic Loading System with Weighing DeviceThe operator just put the linen into the loading chute so that the linen can be weighed automatically and conveyed to the last chute, waiting to be dropped down to the washing drum.The information on loading, weighing, and conveying, as well as guidance for the next step, can be displayed on the controller.

-

PressHydraulic driving is adopted in the design of the pressing system, and the pressure can be up to 45 bar. The pressing performance is monitored graphically. 0-99 programs are available. The pressing system also has the functions of squeezing and rinsing, so that the washing quality is much improved. Stepless pressure regulation can be obtained thanks to the adoption of an enhanced pressing head. Vertical or lateral discharging is available according to the actual condition. Upper and lower steel beams are supported with four steel pillars treated with anti-corrosion. Safer and more reliable. Loading and discharging are controlled with sensors of infrared rays, making the operation simpler and safer.

-

Pass Through DryerAutomatic Through Dryer is applied to loosen and dry the linen that comes out of dewatering equipment such as extractors and presses. It can be connected with an extractor or press. Two options for heating type: steam or gas.

English

English