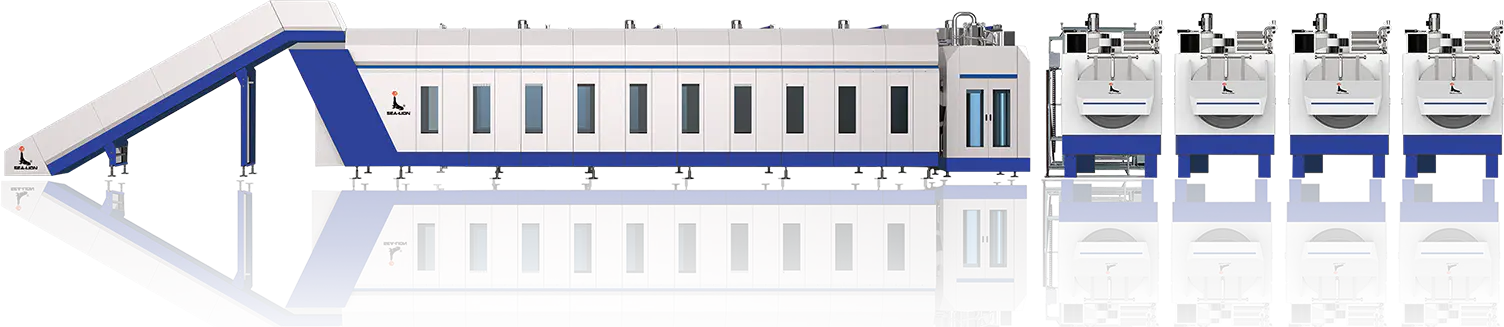

Jiangsu Sea Lion Machinery Co., Ltd. specializes in industrial washing equipment

Provide Customers with Efficient, Energy-Saving and Intelligent Washing Solutions

Categories

-

Four Station FeederThis equipment is designed for smoothing and transferring bed linen into ironers, to ensure the quality of ironing and folding.Eight-inch color touch screen with programmable computer control adopted; Each station is outfitted with a simple digital display for a counting function on items processed, which is a convenient measurement of worker productivity.High efficiency and lower labor costs thanks to the multi-station with easy feeding clamp operation.Linen can be spread and fed evenly under the flapping effect of airflow and the smoothing action of mechanical brushes.When feeding small items, the receiving table can stretch out and draw back automatically for easy operation.Driven by a servo motor, the transfer arms always send linen to the right position accurately.

-

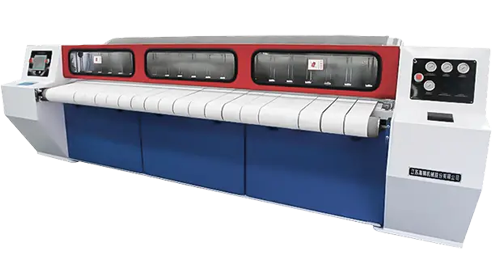

Flatwork&ironer&high Speed Serpentine Flatwork IronerThanks to the variable frequency drive, users can select a suitable speed for different lines.The steam with pressure is supplied through the roll (rolls) so that the ironing area can be heated evenly and effectively. Driven by the combination of belt and chain, big loading and good buffering have greatly increased ironing quality. High speed reducing rate and low noise as a result of the reducer selected. Spindle tape drive is adopted instead of canvas, which can make the transfer smooth. The steam inlet is sealed with a rotary joint to avoid leakage and ensure long service life.

-

High Speed Chest IronerIroning pressure can be adjusted by air cylinder control based on thickness of linen under ironing, which can improve ironingDriven by only-motor, variable frequency control, the ironing speed can be adjusted at will in the work range according to different steam pressure condition, sorts of linen as well as moisture contained.The bridge plate can be heated by whirly steam system, because the holes are underneath of it so that the steam with high speed enable the whirpool to cover all the surface of the bridge plate. The speed and quality of ironing are increased significantly because the flatworks are ironed through the hot surface of the arc bridge plate, and steam consumption is reduced as well.

-

Chest Ironer with Dual Chests Single RollAn internationally advanced double chest heating system is used; the chests are finely machined and configured in a special structure to ensure high ironing quality.Equipped with a big-sized LCD display and an intelligent control system, operator operator-friendly human-machine interface.

-

High Speed Sheet FolderAutomatic folder is applied on folding big ironed or dried linen, such as sheets, quilt covers, as well as table cloths. Low noise, low energy consumption, good performance, beautiful appearance, and reasonable design are the features of the folder. With a big screen and an intelligent control system adopted, the machine has a dialogic function.Folding programs can be selected according to different types of linen. 2-5 folds can be performed under the control of a computer. DC24V on the monitor block can ensure safety and easy maintenance.Thanks to pneumatic valves, it runs fast and reliably and is free of pollution to the surroundings. The output of the controller is done via a relay, and no need for an intermediate relay, which is easy for service and reduces the chance of fault.Adjustable speed can adapt corresponding ironing machine, and it can work together with the ironing machine via communication control, and the folding speed is adjustable according to the ironing speed. Positive-reverse control is adopted for the 4th and 5th folds, with the advantages of no effect from the material and thickness of the linen, better folding results, and a higher folding success rate.The size of linen for each fold is measured with a sensor to ensure the folding line is exactly at the middle.

-

Auto Towel FolderIntelligent control system with a large touch screen display. Available in various languages display menu, easy to operate.The sensors can detect the size of towels and adjust the width accordingly. The lateral fold is done with a folding plate.The coder installed on the shaft measures the length of the towel and selects the folding method accordingly. The first cross fold is done via positive-reverse run and air blow. The innovative machine design will adjust its template to suit the thickness and weight of the towel to ensure good quality folding and execute the second cross fold. The second cross fold is done by a special positive-reverse run and air blow, and an adjustable transport platform is added to ensure good quality.

English

English