Jiangsu Sea Lion Machinery Co., Ltd. specializes in industrial washing equipment

Provide Customers with Efficient, Energy-Saving and Intelligent Washing Solutions

Categories

-

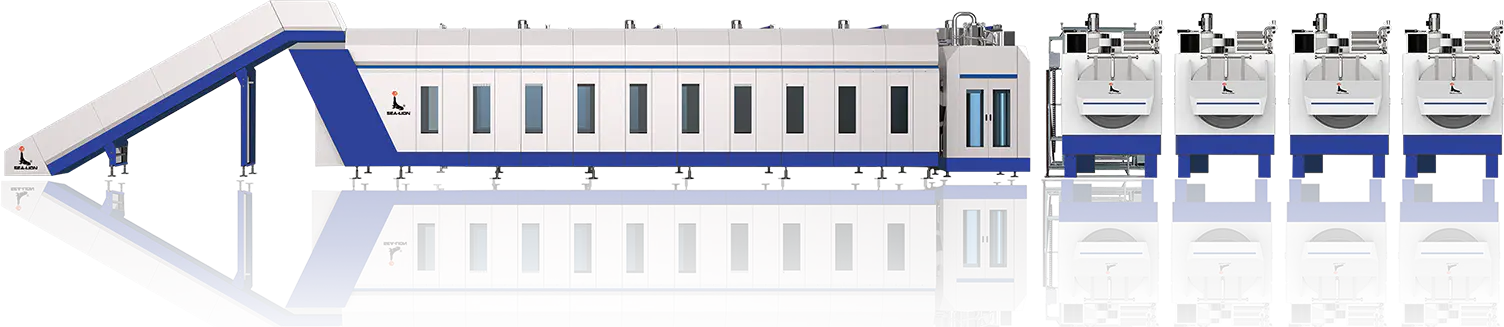

Tunnel Washing SystemThe Continuous Batch Washing system, also named the Tunnel Washing System, has been independently developed by Sea-lion through decades of technological progress. As its shape is like a dragon, it’s also called the Orient Dragon or Sea-lion Laundry Dragon.Sea-lion Laundry Dragon SDX series is welcomed by domestic and foreign customers for its superior performance and high reliability. The transference of linen is done from the bottom so that linen can be transferred smoothly without any risks caused by blockage. The cleanliness is enhanced, and washing quality is guaranteed thanks to the strong washing mechanical force created by the combination of single drum and double drum, along with strong stiffeners andan optimum ratio between conveyor and the volume of chambers.The washing drums of stainless steel and pipes connecting components are designed and fabricated strictly according to the quality standard and hygienic standard. The system can be customised per customers request.

-

Fully Automatic Washer ExtractorMedical Automatic Washer Extractor/ Hospital Washing Machine 15/25/30/50/100kg Main Features1. Adopt a touch-type programmable computer control system, which is highly automatic, safe, stable, and anti-shock.2. Adopt the international latest complete suspension structure to reduce shock, replace the original shock design liquid pressure buffer with springs, which can ensure an ideal anti-shock effect even on higher floors.3. It is with a drum without a compartment and a single door structure convenient to loading or unloading, and reduces the labor intensity and improves the cleanliness level.4. With a fully closed and rear-drainage structure, it is good for environmental protection. The drum and case are both made of high-quality stainless steel, with the advantages of stain resistance and durability.

-

Tumble Dryer1. GZZ and GDZ series automatic dryers are used for drying various types of textiles after washing and extracting.2. Perfect heat transfer and energy saved thanks to a big heater with stainless steel pipes and aluminum fins adopted.3. Microprocessor controller with programmable drying time and temperature setting. 4. Once the drying time is selected, the drum will rotate in clockwise and anti-clockwise directions to tumble dry the textiles inside the drum and automatically stop when it reaches the preset time.5. Door window with tempered glass allows a visual check of the textile inside the drum during drying.6. Over-sized loading door allows easy loading and unloading of linens to achieve higher productivity and reduce human fatigue.

-

Post-finishing machineFinishing machines are specialized equipment designed to enhance the final quality of linen handling in industrial laundry processes. They play a vital role in ensuring that fabrics such as bed sheets, quilt covers, and tablecloths achieve a smooth, neatly ironed, and professionally finished appearance before delivery.This category covers a range of high-performance systems, including four-station feeders, flatwork ironers with serpentine design, and advanced chest ironers. These machines combine intelligent control, precision engineering, and user-friendly operation to improve efficiency, reduce labor costs, and deliver consistent results.Key features across the series include programmable touch screen control, variable frequency drive for speed adjustment, servo-driven feeding and transfer systems, and uniform steam heating for superior ironing quality. With innovations such as airflow-assisted linen spreading, mechanical smoothing, durable transmission systems, and safety-focused designs, post-finishing machines provide reliable performance with long service life.The equipment ensures high efficiency, excellent finishing standards, and streamlined operation, making it a must-have for modern large-scale laundry facilities.

-

Professional finishing systemFinishing machines are specialized equipment designed to enhance the final quality of linen handling in industrial laundry processes. They play a vital role in ensuring that fabrics such as bed sheets, quilt covers, and tablecloths achieve a smooth, neatly ironed, and professionally finished appearance before delivery.This category covers a range of high-performance systems, including four-station feeders, flatwork ironers with serpentine design, and advanced chest ironers. These machines combine intelligent control, precision engineering, and user-friendly operation to improve efficiency, reduce labor costs, and deliver consistent results.Key features across the series include programmable touch screen control, variable frequency drive for speed adjustment, servo-driven feeding and transfer systems, and uniform steam heating for superior ironing quality. With innovations such as airflow-assisted linen spreading, mechanical smoothing, durable transmission systems, and safety-focused designs, post-finishing machines provide reliable performance with long service life.The equipment ensures high efficiency, excellent finishing standards, and streamlined operation, making it a must-have for modern large-scale laundry facilities.

English

English