-

Stp.1

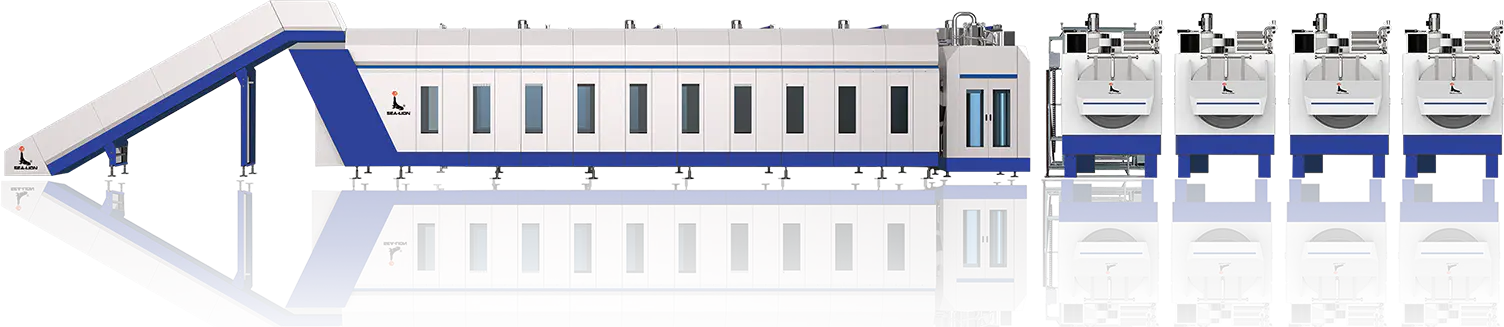

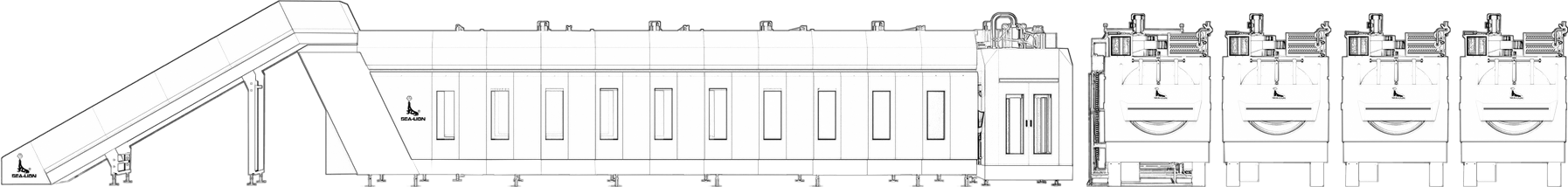

Product design (customize the machine design according to customer needs)

-

Stp.2

Engineers modify the design of the drawings according to the customization requirements.

-

Stp.3

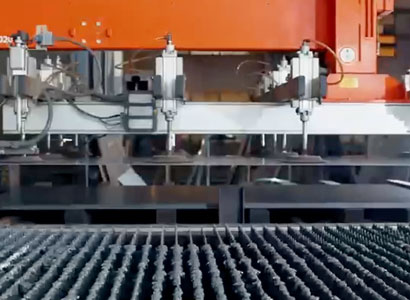

Procurement of raw materials

-

Stp.4

Processing of components

-

Stp.5

Overall assembly of the machine

-

Stp.6

Debugging and inspection of the machine (conduct no-load and load debugging, and gradually inspect and test the safety performance of electrical components)

-

Stp.7

Treatment of surface details and packaging (select appropriate packaging according to different transportation methods)

English

English